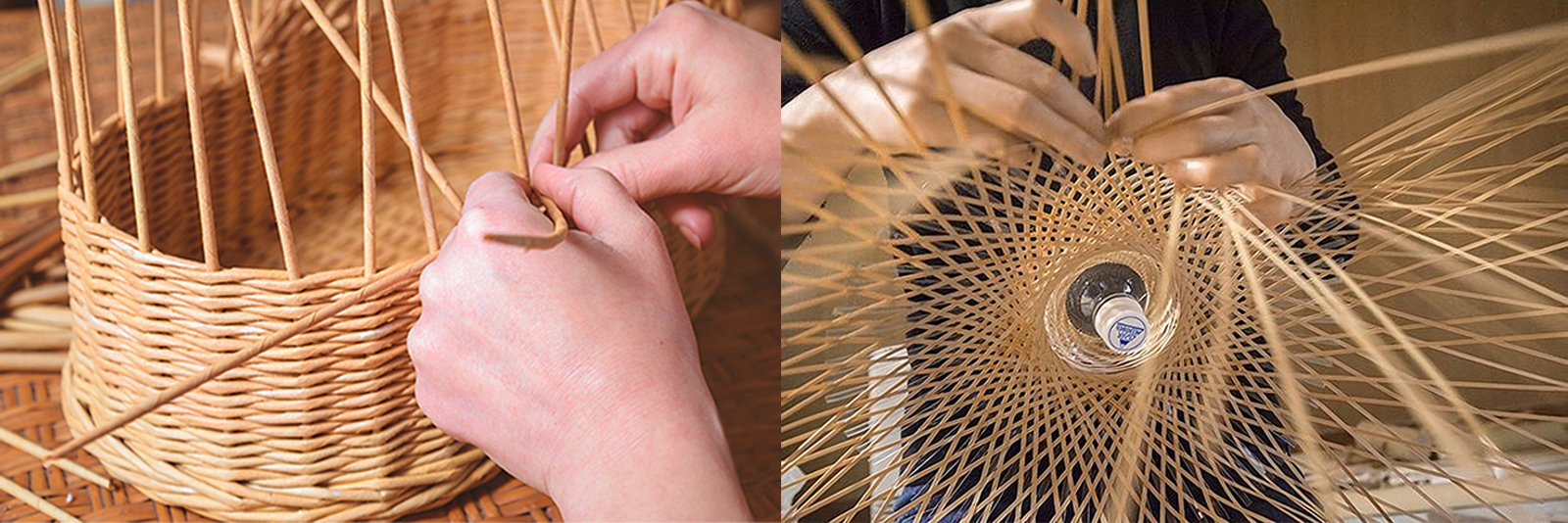

Rattan lamps are generally made using purely handmade weaving techniques. The following will discuss in detail the production process of rattan lamps and the techniques of hand weaving.

Prepare raw materials:

1. Rattan: Choose good quality natural rattan, such as vine or cane bark. The cane should be free of damage and insect damage and should be softly adjustable.

2. Other tools: scissors, rope, needles, knives and other auxiliary tools.

Make the braided base:

According to the design requirements, prepare a woven base of appropriate size and shape. The base can be constructed from a metal or wooden frame, or from woven rattan.

Woven lampshade:

1. Cut the rattan accurately and determine the length and shape according to the design requirements.

2. Use wire or rope to secure the rattan to the woven base and determine the initial position according to the design requirements.

3. Use different weaving techniques, such as cross weaving, wrap weaving, simple overlay, etc., to weave the rattan in sequence. When weaving, you need to pay attention to maintaining rhythm and tension to ensure that the overall weaving is even and stable.

4. According to the design requirements, some special weaving techniques and patterns can be added, such as twisted weaving, pattern weaving, etc., to increase the decorative effect.

Complete the lampshade:

1. As the weaving progresses, adjust the position and direction of the rattan, as well as the height and shape of the weave, to achieve the lampshade appearance required by the design.

2. Trim and adjust the rattan as appropriate during the weaving process to maintain the flatness and consistency of the lampshade.

3. When the last rattan is woven, secure it to the previously woven rattan to make the overall weave tight and stable.

4. Use rope or wire to tie the top and bottom of the lampshade tightly to ensure a stable overall structure.

Other processing:

1. Clean the lampshade and remove excess ropes or threads, etc.

2. The rattan lampshade can be polished and varnished as needed to increase the decorative effect and protection.

In the production process of rattan lamps, hand weaving technology is crucial:

1. Master precise cutting techniques to cut cane to desired length and shape.

2. Flexibly use different weaving techniques, such as cross weave, wrap weave, overlay weave, etc., to adapt to different design and pattern needs.

3. Pay attention to details and tension to ensure that the rattan weaving is smooth, even and stable. Trim and adjust as needed to maintain the consistency and beauty of the overall weave.

Since rattan lamps are purely handmade, each production process may be slightly different. Designers and producers can flexibly operate and improve them according to their own creativity and imagination, making the lamps a unique work of art.

As the core element of layered lighting, pendant lights play an important role in creating a warm atmosphere. By properly matching pendant lights with other lamps and combining the functional requirements of different scenes, you can easily create a comfortable and beautiful lighting environment.

I hope the design tips and suggestions in this article can provide inspiration for your lighting design. If you are considering optimizing the lighting of your home or commercial space, you might as well try layered lighting with pendant lights to experience the unique charm of light.

If You Are in Business, You May Like

Post time: Jan-11-2025